Please excuse the amateur pictures, I am an engineer not a photographer.

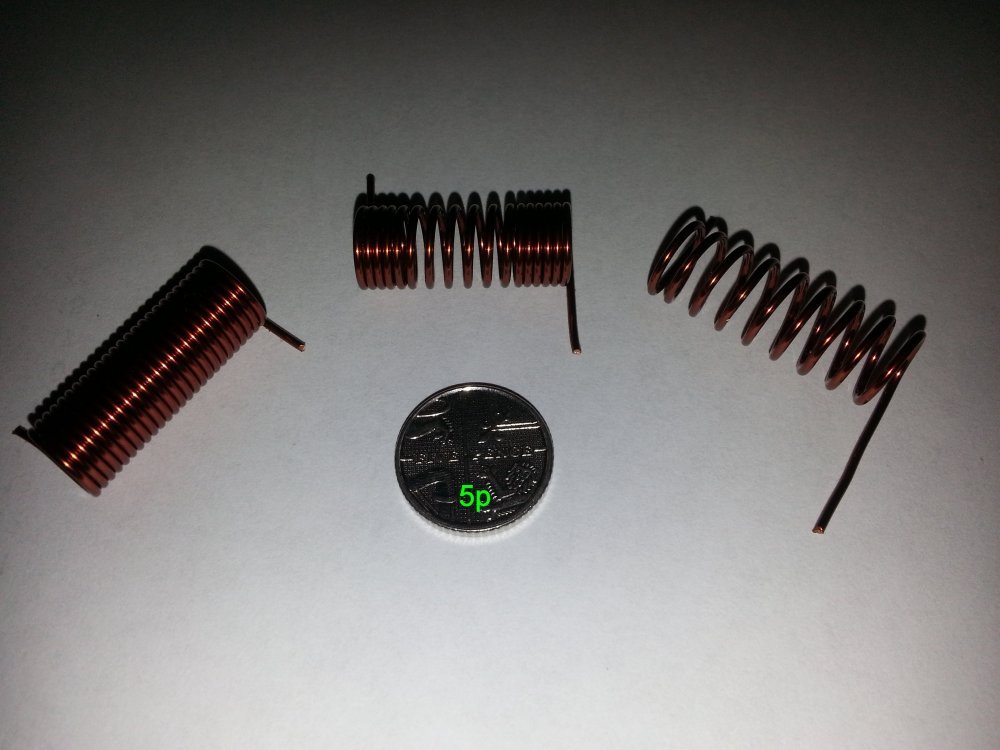

3 coils all wound on a 8 mm diameter mandrel with 1 mm diameter enamelled copper wire. Wound using a CNC coil winder. Just a change of

the command code made these 3 different coils on the same mandrel.

Mechanical stripping and dip soldering.

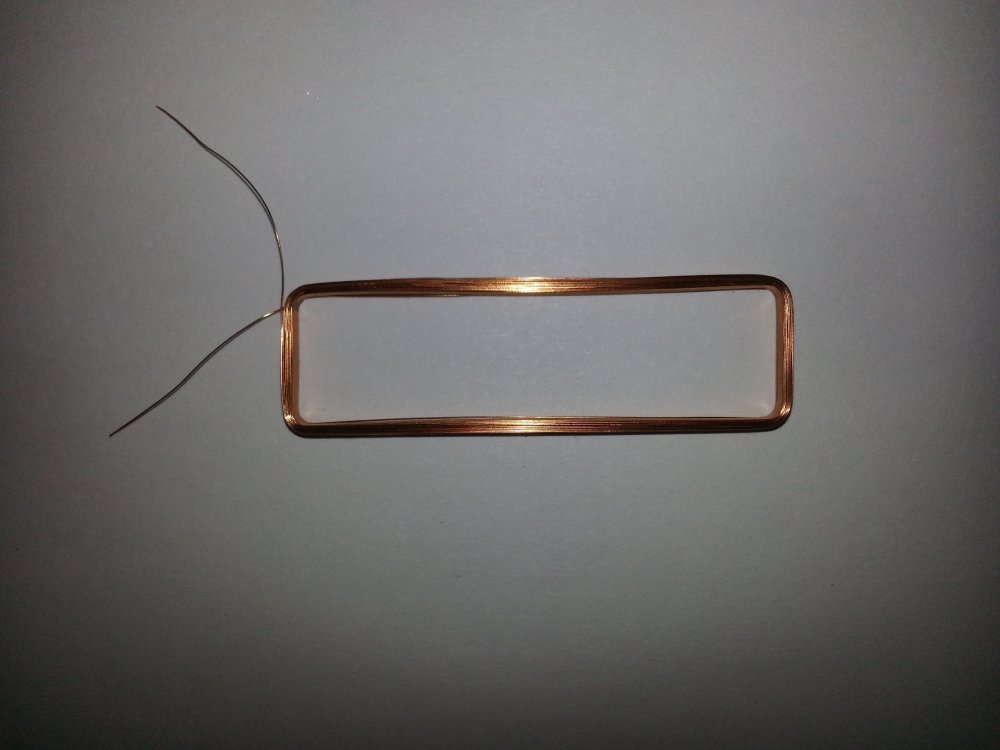

LF RX antenna coil - Coil ID = 52mm x 14mm x 2.8mm thick. 100 turns wound with 38 SWG self bonding wire. This coil was also wound on a

CNC coil winder using an orthocyclic winding process.

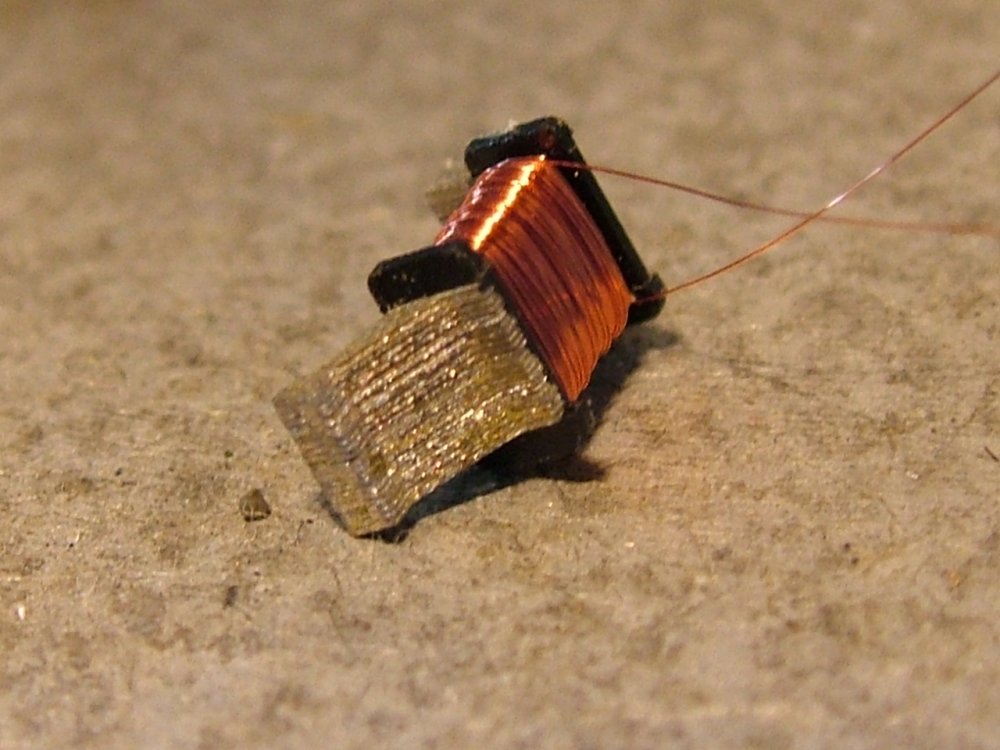

Digital recording head erase coil. The core is 9 mm long. The wire dia. is 0.056 mm. There is 235 turns on the core.

Digital recording head write coil. The core is 9 mm long. The wire dia. is 0.063 mm. There is 250 turns on the core.

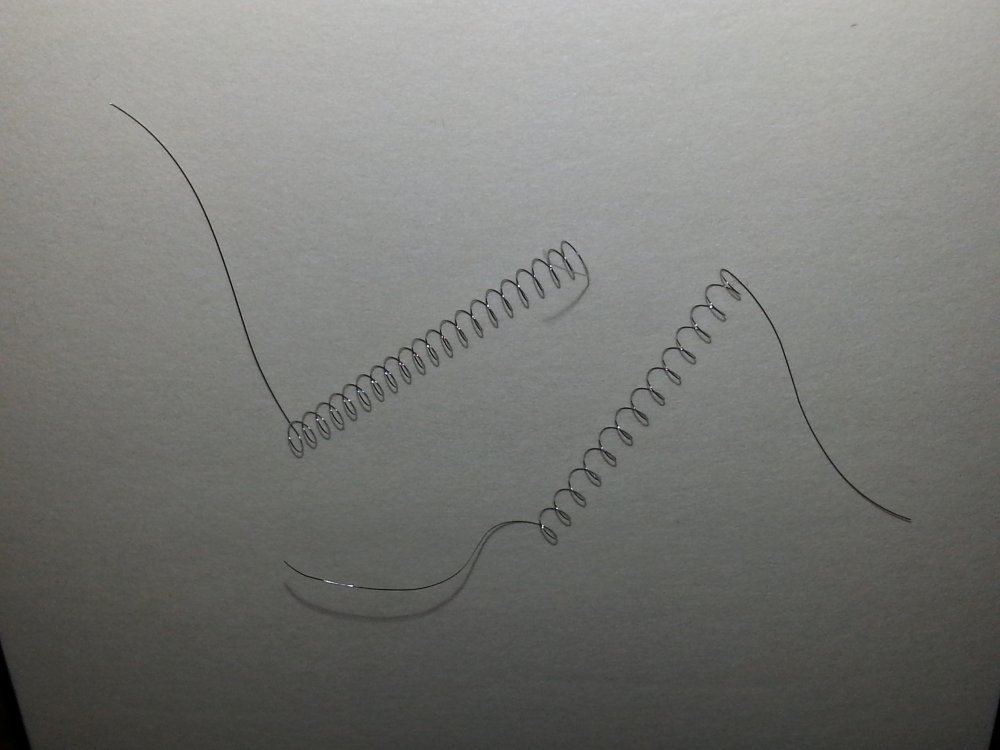

Heater elements 1.5mm diameter by 24mm long as an example. Wound with 80/20 Nickel Chrome Bright Annealed 0.081mm diameter wire.

The coils can be supplied with or without leads.